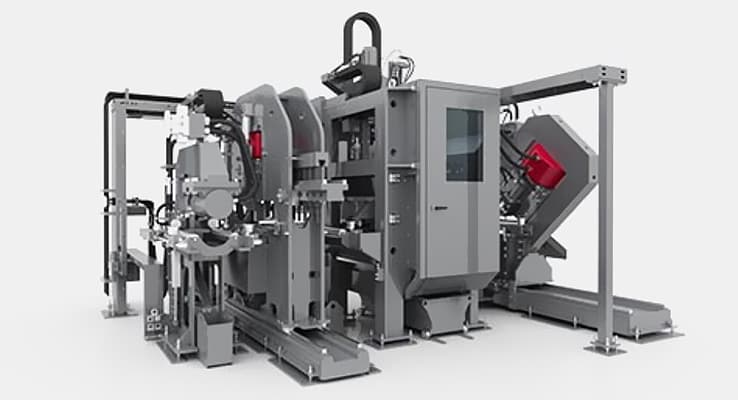

Vacuum Chamber

Beam Layout Welding software can be downloaded remotely via a networked PC. The program also contains a data logger that keeps a log of machine operations for a day. This option allows the production of beams up to 84 inches in size, instead of the 72 inch standard. The system can be modified to support larger web sizes.